Go greener with dairy packaging

Dairy processors have many options today for enhancing the sustainability of their product packaging.

Thinking about making some sustainability-minded tweaks to your dairy packaging? Don’t think too long. When it comes to food and beverage packaging, consumer expectations have never been “greener” than they are today.

“Sustainability is no longer a ‘nice to have’ but a ‘need to have’ when it comes to packaging,” Michael Moren, commercial director for Putnam, Conn.-based Impact Consumer Products Group (ICPG) explains. Consumers are more knowledgeable than ever, he adds, and are “actively looking to brands to help them make environmentally responsible decisions and inform them of the sustainability attributes of their packaging.”

Heather Chandler, president of Gilbertsville, Pa.-headquartered Sealstrip Corp., notes that recent research shows that during the past year, two-thirds of consumers opted for packaging based on its sustainable attributes. Moreover, more than half of consumers are likely to avoid buying a product with packaging they view as being harmful to the planet.

“Despite the pandemic’s effect on the economy, the majority of consumers will still pay more for packaging with additional benefits,” she says.

Consider alternatives to plastic

Dairy processors have many options today for enhancing the sustainability of their product packaging. For example, manufacturers already are reworking traditional packaging options in an effort to reduce plastic content, notes Jonathan Vierns, manager, North American sales for Oldsmar, Fla.-based Osgood Industries LLC, a Syntegon company.

“Paper-based cups are often the material of choice, as they have a better ecological footprint,” he says. “To keep products convenient, manufacturers use them in combination with other sustainable packaging options. Case in point: Experts predict that plastic snap-on lids for yogurt cups will gradually disappear from the refrigerated section. Here, reusable lids offer an alternative; they can save several thousand tons of plastic waste per dairy manufacturer every year.”

Vierns points out that alternatives to snap-on lids for refrigerated beverages already are in the works. One initial concept features a peel-off lid with an integrated drink opening.

“In the future, cup solutions for viscous products that are made of plastic/paper mixtures, as well as mono-material solutions, will replace composite materials,” he predicts.

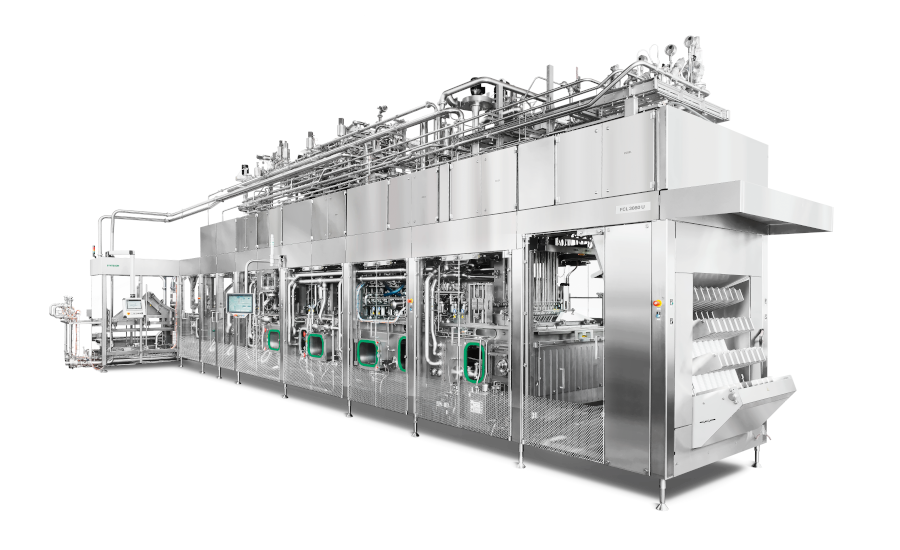

Ampack and Osgood filling machines for pre-made cups fill liquid and viscous food products into paper or mono-material packaging, he adds. They are available in clean, ultra-clean, and aseptic versions designed according to 3-A Sanitary Standards requirements.

“Manufacturers can choose to sterilized cups with either UVC radiation, a pulsed-light system or H2O2 steam, depending on the machine type,” Vierns notes.

Beth Romano, product manager in the Consumer Goods division of Huhtamaki North America, De Soto, Kan., agrees that plastic reduction is a big opportunity for dairy packaging and believes that paperboard spells opportunity for yogurt and other cultured dairy items.

“Paperboard can safely deliver cultured products without compromising quality or shelf life,” she maintains. “Litho-printed graphics directly on the container provide high-resolution image capabilities without the need for secondary labels or wraps. FSC certification [ensures] the paperboard is sourced from responsibly managed forests protecting current ecosystems and supporting healthy forests for future generations.”

For fresh milk and juices, paperboard cartons come with a carbon footprint that is 32% lower than that of high-density polyethylene (HDPE) and 60% lower than PET bottles, notes Patrick Verhelst, chief marketing officer for Oslo, Norway-headquartered Elopak. He cites data from a May 2021 lifecycle analysis from Anthesis.

Verhelst adds that Elopak recently launched its natural brown board cartons — which surpassed a billion units in early 2021 — in North America.

“These cartons have a lower CO2 footprint than conventional cartons, owing to reduced wood consumption and the elimination of the bleaching process,” he says. “They remain renewable and recyclable, while their rustic-looking natural design instantly stands out on the shelf and helps companies to communicate their products’ sustainability credentials.”

Another renewable option is Pactiv Evergreen’s PlantCarton package. Katie Simmons, marketing manager for the Lake Forest, Ill.-based company, notes that 70% of that carton is made with paper, a renewable resource.

“Pactiv Evergreen cartons are recyclable and made from trees grown in forests where responsible forestry practices are used, the overall rate of growth exceeds removal, and environmental impacts are minimized,” she says. “About 55% of the energy used to make the paper in PlantCarton packaging comes from biomass, a renewable energy source.”

For ice cream packaging, plastic-related sustainability tweaks can include a reduction of the poly coating that serves as a moisture barrier and sealing layer, says Murray Bain, vice president, marketing for Stanpac, Smithville, Ontario. Another step could be the addition of post-consumer-recycled fiber.

“We are also beginning to offer coatings that replace polyethylene all together so the product can be easily recycled in current recycling systems,” he says. “Compostable options for cold cups are also being tested currently.”

Encourage recycling

There is currently a greater focus on recycling amid all of the negative press related to plastic, notes AJ Miller, director of marketing for Silgan Closures, Downers Grove, Ill.

“When consumers get their packaging into the recycling bin, it keeps it out of our oceans,” he stresses.

Consumers are learning to place the caps on milk and other bottles, too, when recycling the containers, Miller notes. That’s a good thing, as the caps are too small to get through the recycling process alone. However, consumers could benefit from additional recycling education, he suggests.

“Milk jugs are typically made from HDPE. Recycled HDPE is in high demand because it works great for post-consumer resin,” he notes. If consumers are educated and recycle more, there will be additional recycled content to include in new packaging.”

Miller says dairy brands could educate consumers via on-pack communication. Brands could leverage the How2Recycle labels (https://how2recycle.info/) from GreenBlue to do so.

For its part, Pactiv Evergreen partnered with the Carton Council, Simmons says, an organization that is committed to diverting cartons from landfills by expanding recycling access and participation rate.

“Carton Council has made important and remarkable progress in the last decade to help bring carton recycling to the majority of U.S. households,” she says.

In part because it cannot be recycled at scale, polystyrene has fallen out of favor for use in applications such as portion-controlled creamer cups and multi-packs, Moran notes. But much of the existing equipment for form-fill-seal dairy packaging is designed to process that material. ICPG offers its XPP solutions to deliver a solution for alternative polypropylene packaging that also represents a better sustainability proposition at a cost savings compared to polystyrene and PET.

“Our solutions are lighter-weight and therefore offer a more efficient use of resources — and are recyclable as polypropylene even in high-barrier form,” he says. “Our materials also offer compatibility with existing FFS equipment and processes, so it will not require excessive capital expenditure or a wasteful overhaul of existing equipment to achieve successful processing.

Perhaps even better than recyclable packaging is packaging that completely decomposes after use. Australian company PaktoEarth offers solutions for recyclable, naturally decomposing plastic packaging, notes Arnold Lawner, advanced materials. Its Raws-tech, a thermal biodegradable plastic that complies with the international degradation standard, naturally degrades when exposed to either UV light or thermal heat, with zero to limited oxygen.

“Unlike plant-based plastics, which require commercial/industrial treatment at 60 degrees Celsius continually for two days to break down followed by a lengthy process, PaktoEarth Raws-tech requires no special treatment,” he notes.

The technology can be used in any polypropylene or polyethylene plastic, Lawner says, for packaging ranging from flexible food wrap to rigid food containers. A “stall date” is built into the formulation to hold back the start of the natural decomposition process from six months to four years following manufacture. Once the stall or trigger date expires, the products will naturally decompose in two years — in natural compost or in a landfill.

Plastic has its place

Plastic dairy packaging also is ripe for sustainability-minded tweaks. For example, less plastic could be used in some cheese packaging, says Travis Klug, dairy marketing manager for Amcor Flexibles, North America, part of Zurich, Switzerland-based Amcor.

“This could be achieved by reducing the thickness of the packaging material or, in some cases, by removing excess packaging,” he says.

The inclusion of recycled content within the cheese packaging also could help in the development of a “more sustainable circular economy,” Klug notes, as well as in the reduction of energy use and greenhouse gas emissions.

“Innovating packaging so that it’s designed to be recyclable is the most critical step in any dairy processor’s sustainability journey,” he adds. “This requires packaging suppliers to develop and supply mono-material solutions that are compatible with existing recycling streams for PE films.”

The prevention of food waste due to shelf-life issues also is a key part of the sustainability equation on the flexible packaging front. Sealstrip’s newest FreshPak iteration, the FreshPak BarrierPlus system, features a barrier reseal to promote long-lasting freshness in product such as sliced cheese, Chandler says.

“The BarrierPlus reseal is unlike other reseals, as it opens within the end seals of the package, avoiding harmful air and moisture transference that occurs where the barrier film seals over typical reclose features,” she explains.

On the rigid side, PET packaging is recognized as the most sustainable packaging material and offers dairy brands sustainability advantages, says Laura Claus, sustainability manager for Amcor Rigid Packaging. She points to a soon-to-be-released report from the National Association for PET Container Resources that notes manufacture of a PET bottle produces 51% less CO2 emissions than a comparable aluminum can and 120% less than a comparable glass container.

“PET is also shatterproof, hygienic, and is superior for preserving and protecting a product,” she adds. “These advantages continue to drive the Amcor R&D and Innovation teams, which is encouraging because we know that up to 80% of a product’s environmental impact is determined during the design phase. These advancements include lightweighting efforts to reduce bottle weight by up to 33% and doubling the amount of recyclable material used in our products over the last two years.”

And closures on the rigid side are getting more sustainable. As Miller notes, Silgan Closures is engaged in product development in three different areas. It is developing closures with less material, with the F15 carton fitment being the company’s latest design for lightweighted closures. In addition, it is making closures with recycled materials — its 38-millimeter DBJ closure, widely used in dairy applications, is now available in a version with PCR for customer trials. Finally, Silgan is developing renewable closures based on sugarcane.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!